Manufacturing an assembly in our workshop

As soon as the equipment is delivered to our workshops, a quality control is carried out to certify all the parts we receive.

The Palamatic Process technicians carry out the pre-assembly of each piece of equipment at Palamatic Process' headquarters. This procedure makes it possible to check the conformity of the delivered parts.

Assembly in workshop B

Assembly in workshop C

Quality control of received parts

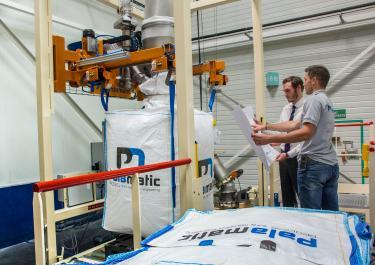

Following assembly, under real-life conditions are carried out tests (FAT). This step is performed with the presence of our engineers.

This step is crucial to validate that the equipment requested complies with the specifications.

The principle is to carry out a final verification of the different devices and the process.

During this phase, the client can be present to carry out the verifications with the project engineer.

Assembly in workshop A

Assembly in workshop A

Client FAT

Assembly on your site

We perform or supervise every step of your project from assembly to final commissioning. We can offer you a complete quality service with respect of your deadlines. The installation of our equipment in your premises is performed by our technicians everywhere in the world.

Pre-assembly is carried out in our workshops. The assembly of your production line includes handling, mechanical assembly, supporting piping and electrical wiring.

Our assembly service includes:

- Mechanical and electrical supervision

- Mounting of the equipment (provided by Palamatic Process)

- Installation of pipe supports, cable tracks

- Supporting of the equipment (provided by Palamatic Process)

- Electrical wiring between the cabinet and systems

- Pneumatic wiring and connection

- Ground handling and lifting equipment (forklift truck, telescopic forklift…)

- Operator access equipment (nacelle, scaffold)

Our technicians and supervisors are qualified: chemical hazards N1 & N2, Caces - safe driving aptitude certificate - (forklift truck, aerial platform)

In subcontracting: MASE certification (manual for the improvement of company safety)

On-site assembly

On-site electrical wiring