Case studies - Energy

Palamatic Process works with a large number of customers in the energy sector in all its forms. Fossil fuels (gas, oil, coal), nuclear power and renewable energies are all sectors in which powders are used directly or indirectly.

Case studies with our customers

DeNox of a powership

Thermics Water and smoke Energy

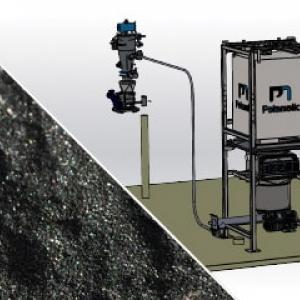

Pneumatic conveying and ashes storage

Water and smoke Energy

Disposal, dosing and pulping system

Batteries and componants Energy

Automation of a super bag unloading system

Batteries and componants Energy

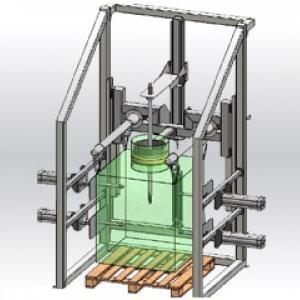

Discharging station of big bags of cadmium in very high containment

Batteries and componants Synthetic chemical Chemical Energy

Big bag discharging and pneumatic conveying

Thermics Energy

Discharging of storage silos

Thermics Energy

Big bag filling in thermal power plant

Thermics Energy

Preparation of electrolyte pool charges

Nuclear Energy

Mixing and feeding line for raw materials for cementing

Nuclear Energy

Palamatic Process has extensive experience with clients in various sectors of the energy industry. Fossil energies (gas, oil, coal), nuclear energies, as well as renewable energies, are sectors where the use of powders and bulk solids are present in a direct or indirect method.

- Bulk handling equipment is extensively used In the field of coal.

- In the port and oil fields, the dosing of additives is a frequent activity for Palamatic Process applications.

- Palamatic Process also has experience in the nuclear field. Our teams are specially trained to intervene on production sites (power plants) and also on reprocessing sites.

- Palamatic Process powder applications are also found in the manufacture of solar panels using silicon. Applications in the handling of machefer (solid residues of urban waste) have been handled by Palamatic Process in order to load big bags with the ashes for hazardous waste burial and long-term storage.